Quality Process

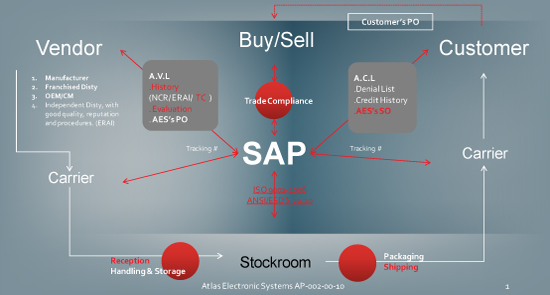

BESA continues to vastly improve its quality control processes. Customer satisfaction is our priority by providing not only the best price and delivery the market can offer but also guaranteed 100% quality products. BESA will be implementing state of the art technology with testing equipment and currently implemented internal protocols such as the BESA Sourcing Approval Integration (SAI) and Vendor Management Program (VMP). With these two protocols in place, we can track products based on our air tight supply chain where we can always trace items back to the original source.

Sourcing

All lead-time buys and/or spot buys are bought through Authorized Distributors and/or direct channels. (Parts can be tracked and full traceability can be shown on the package via lot code, batch code and date code)

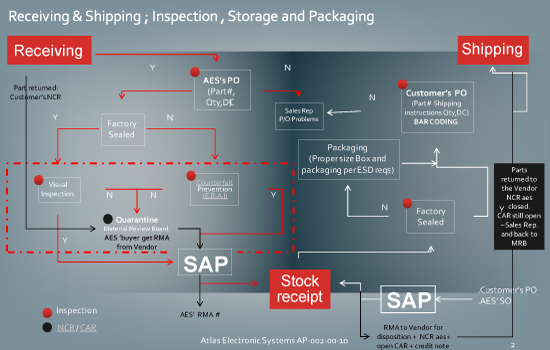

Inspections

Our Quality Control process adheres to strict guidelines, which include:

- Vendor Management Program

- Supplier Monitoring

- Visual Inspections of all open bag materials

- Ensuring that all materials are in factory sealed packages and packaging labels attached to show traceability back to the factory.

Shipping process

- MBB will be used for any and all re-packs

- MSL labels will be included to all re-packs

- Dry packs will come with desiccant and HCL card for all

- All items especially modules are air-tight

En

En Fr

Fr